The Construction of the Data Center Drives the R&D, Production and Test of GIGALIGHT’s Active Optical Cables – Real Knowledge Comes from Practice

Hardware Compatibility Design

It includes electrical equalization, impedance matching design, and optimized design of emitted light eye diagram. Its goal is to realize that the active optical cables can work with any mainstream brand of network cards and switches globally. For example, the optical device selection and verification projects need to consider completeness. For some ROSA devices, if the selection is improper or the verification is insufficient, the received signal may have a bit of error in a particular range. Besides, the design of the soft-start circuit needs to consider the timing impact. Otherwise, a problem cannot start the subsequent application to some brands of network cards.

Software Compatibility Design

Some alarms and underlying logic matching problems are solved by upgrading the cloud firmware. GIGALIGHT’s products are mainly exported to international markets. However, different application scenarios have different requirements for software compatibility. For example, Korean customers are unique in controlling the alarm time of loss of signal (LOS) and the normal shutdown of the low power function (the protocol is to open low power).

Reliability Design

It includes safety design, electromagnetic compatibility design, and environmental reliability design.

Safety Design

To ensure personal safety, property, environment from injury and loss, GIGALIGHT designs electric shock protection, energy danger, fire, heat-related danger, mechanical danger and laser radiation control with the most stringent requirements, which meet international and domestic standards, such as IEC 62368-1, EN 62368-1, UL 62368-1, GB 4943-1, IEC 60825-1 and so on. For example, Active Optical Cables can usually work via the insulation design when equipment leaks electricity and suffers from lightning strikes and other faults. These measures are taken to ensure the product’s safety in extreme situations.

Electromagnetic Compatibility Design

It is always challenging to ensure products do not exceed standard radiation and be not affected by external electromagnetic interference. GIGALIGHT’s Active Optical Cables are verified through internal and external testing, like PCB design, structural design, device selection, etc., and comply with FCC and CE regulations. In the radiation disturbance test, the actual value is lower 6dB than the limiting value, and the external radiation performance is deficient. In the electrostatic discharge immunity test, the acceptable level is 4 (8KV contact discharge, 15KV air discharge). The products usually work error-free and have excellent protection against static electricity. In the radiation disturbance test, the product meets Class A’s requirements and has good anti-electromagnetism disturbance ability in the 10V/m proving ground.

Environmental Reliability Design

All are with the strict GR-468 standard through material selection, structural design, critical process control (such as coupling, gold wire welding, glue curing, etc.), and complete internal reliability testing equipment verification. Therefore, GIGALIGTH can serve customers reliably for a long time. The reliability verification, ageing and screening of chips are crucial. In practice, the reliability and yield of rising VCSEL chips are still not compatible with network applications over 25G. COB ageing selection needs to follow the ageing conditions suitable for the chip strictly, and there may be risks in applying a unified standard for different optical chips.

Product Structure Interference Design

The field environment raises some risk of structural interference. Hence, the design of product structure interference is of much concern. For example, consider the design clearance between transceivers’ cover and the plastic LENS, whether there is a risk of the cover pressing the LENS, and how to screen bulk-production items. The matching design of the MPO adapter used in the high-speed transceivers needs to consider the external force influence when plugging and unplugging the jumper. Consider the matching problem of cable plastic and shell. There are many structural design details, and if the design is not careful, there may be a risk of product application interference.

Rapid solution for client problem solving

GIGALIGHT has established an RMA visualization system, which promotes the rapid handling of customer complaints from the process. The matched failure case database can quickly locate the root cause of new client problems and respond quickly. GIGALIGHT can get early warnings and promote improvements quickly for delivery, products with high failure rate and recurring problem. The customer service RMA visualization system has played a good role in rapid response, collaboration, quality warning, and experience sharing.

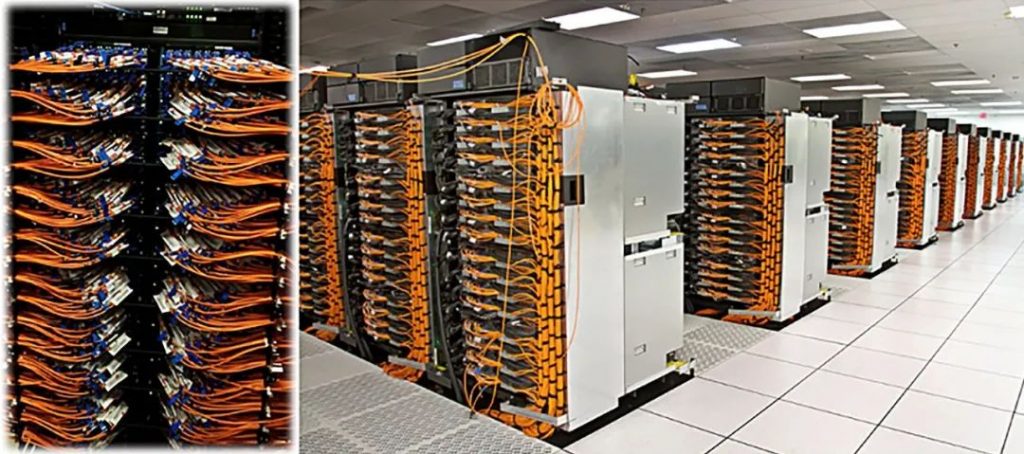

An open network requires open optical network hardware. Through the large-scale deployment of more than 3 million 10G&25G active optical cables in domestic Internet companies, GIGALIGHT has achieved a leap from cognition to practice. And so far, the active optical cables constructed around the world have not caused any operational obstacles and long-term risks to customers.